Trend of Development

Digital transformation illuminates the outlook for manufacturing

01With the further deepening of the "intelligent manufacturing", industry 4.0, intelligent manufacturing, industrial Internet...... All show that manufacturing industry of China is transforming and upgrading with new technologies.

The traditional shoe manufacturing industry, which is facing severe challenges, is the one most likely industry to be reborn through technological transformation, and it will break the traditional "old model" through digital transformation and inject "new vitality". The application of the IOT, big data, blockchain and other technologies will accelerate the integration of industry and finance, make full use of auto equipment to improve production efficiency and reduce labor costs, comprehensively optimize the production process and improve the production process, through intelligent software, IOT and other technologies to achieve scientific and efficient production scheduling, real-time grasp the progress, so that the production can be perceived, visualized.

From building automated workshops to intelligent factories, more shoe factories have joined the team of digital transformation and upgrading, and have become the intelligent pioneer in the tide of digital transformation of the industry.

With the new IOT technology, the shoe enterprises are evolving to the intelligent management system

Industry Feature

Shoe enterprises face consumer demand, production management,

operating costs, employees and other challenges.

02

Consumer demand

Industrial reform is imminent

With the improvement of living conditions, e-commerce is popular, and consumers' demand for shoes tends to be diversified and personalized, with the pursuit of high cost performance.

This requires the shoe factory must be small batch, fast production, fast delivery,,increased the contradiction between the customer and factory.

Operation cost

Operating costs remain high

Shoe enterprises supply chain end is large-scale production, Slow reaction and long cycle.

Production management

Management efficiency needs to be improved

At present, the information level of shoe enterprises is low, the benefits of production capacity mainly rely on the professional quality of the separate layer management personnel, and the data is scattered, the communication cost is high, no visual management, all rely on experience decision.

Employee

The fault line of employees is serious

Shoe manufacturing industry is a labor-intensive industry, it is difficult to recruit, aging is aggravated, and the education level of employees is generally low, the working environment and personnel quality are not suitable for the operation of complex system.

Shoe factory infrastructure construction is backward, management sheet shape, data island, intelligent construction is slow

-

infrastructure

200 people and below —— automation, lean transformation

- · Plant without planning: the factory area is small, the large automatic equipment can not be put, low floor can not hang logistics line, space utilization rate; surface materials warehouse, cutting workshop, sewing workshop, back ironing, sorting, packaging, 5 modules unreasonable layout, poor cohesion, waste of handling time;

- · Less automatic equipment: less automatic sewing equipment, can only rely on skilled workers to ensure the quality, skilled workers are difficult to recruit, time and personnel costs are high. There is automation equipment, but the equipment layout and quantity matching is not reasonable, the production efficiency is still not improved;

- · Unreasonable process layout: no assembly line is formed according to the shoe style process, and the secondary backflow is serious; the off-line process is many and far, and the handling cost is high;

- · 5S management disorder: various tools are not classified, marked and visually managed; unclear equipment after the work may cause equipment damage and delay the construction period.

-

Digital platform

Problems faced by large-scale enterprises —— Intelligent upgrade

- · Software system chimney forest: independent planning, health, use. The systems are not interconnected, and there are problems of repeated construction;

- · Data is not converged, lack of analysis and mining ability: each system database is independent, data standards are inconsistent, and lack of data analysis and processing tools, unable to mine effective data to further support accurate decision-making.

-

Intelligent application

200 people and below —— automation, lean transformation

- · Less application system construction: insufficient coverage of business scenarios, low management efficiency;

- · Low degree of intelligence: there is an application system, but the degree of intelligence is insufficient, mainly focused on business information, single function, lack of algorithm support, not realized comprehensive perception, intelligent decision-making, automatic control.

Solution

Automation

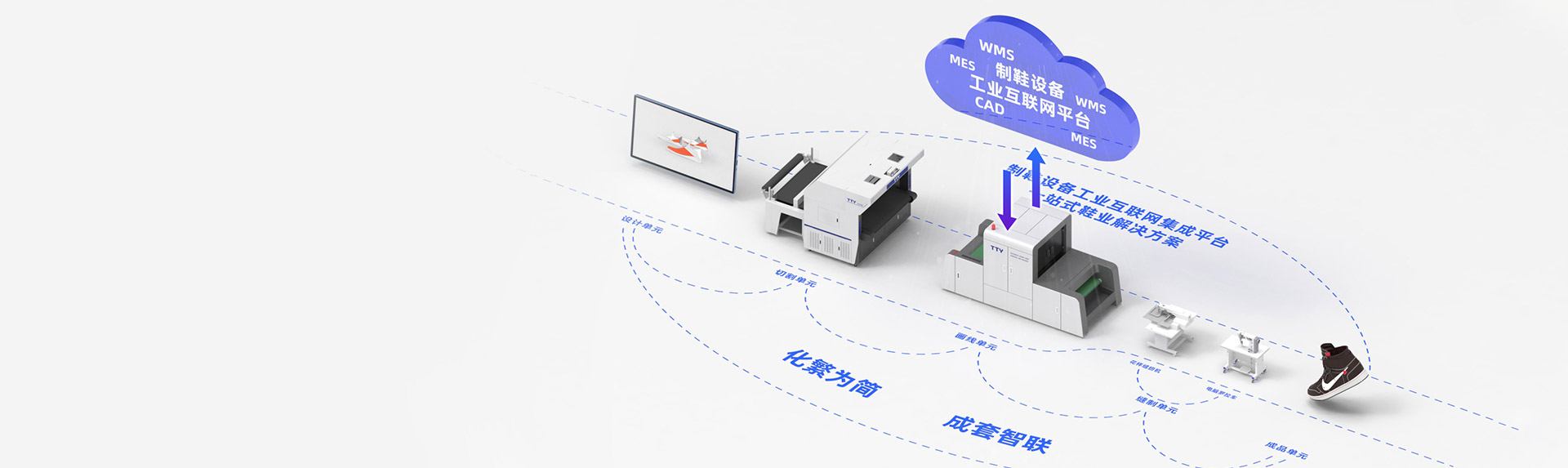

Complete set of automation hardware equipment, from seam, seam to seam one-stop supply

Lean

Provide research and rectification reports on factory layout, process adjustment, production line analysis, standardized operation and efficiency analysis, to guide the factory to enter lean production

Digitalize

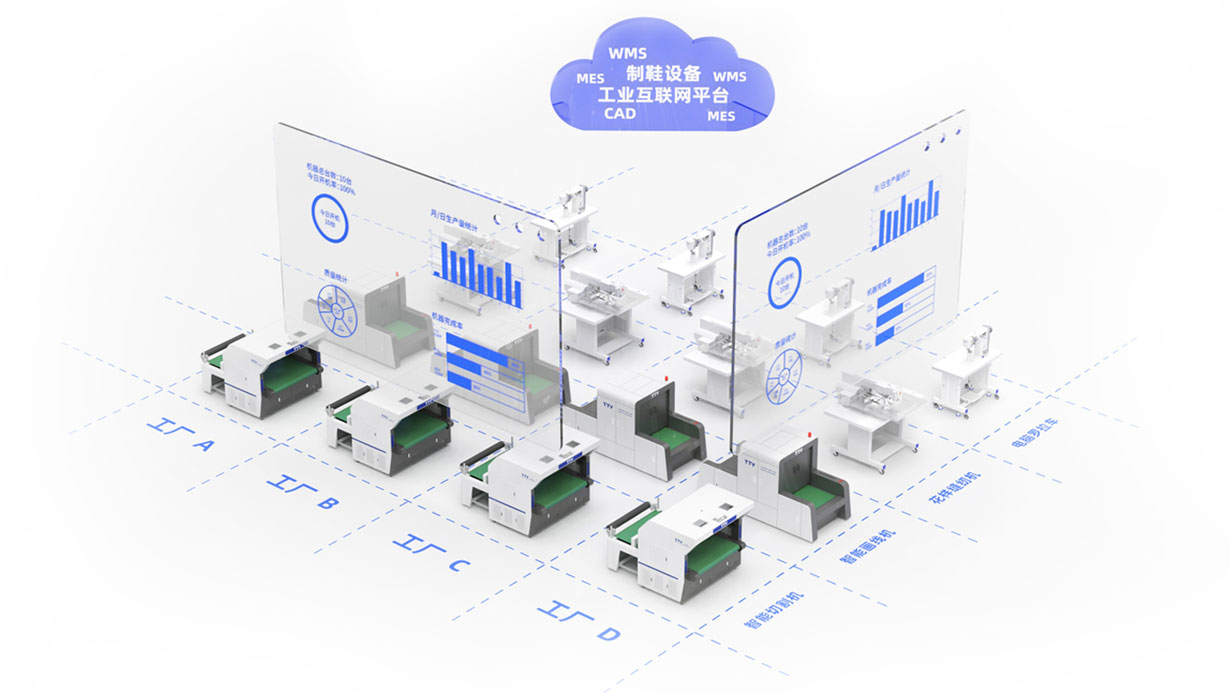

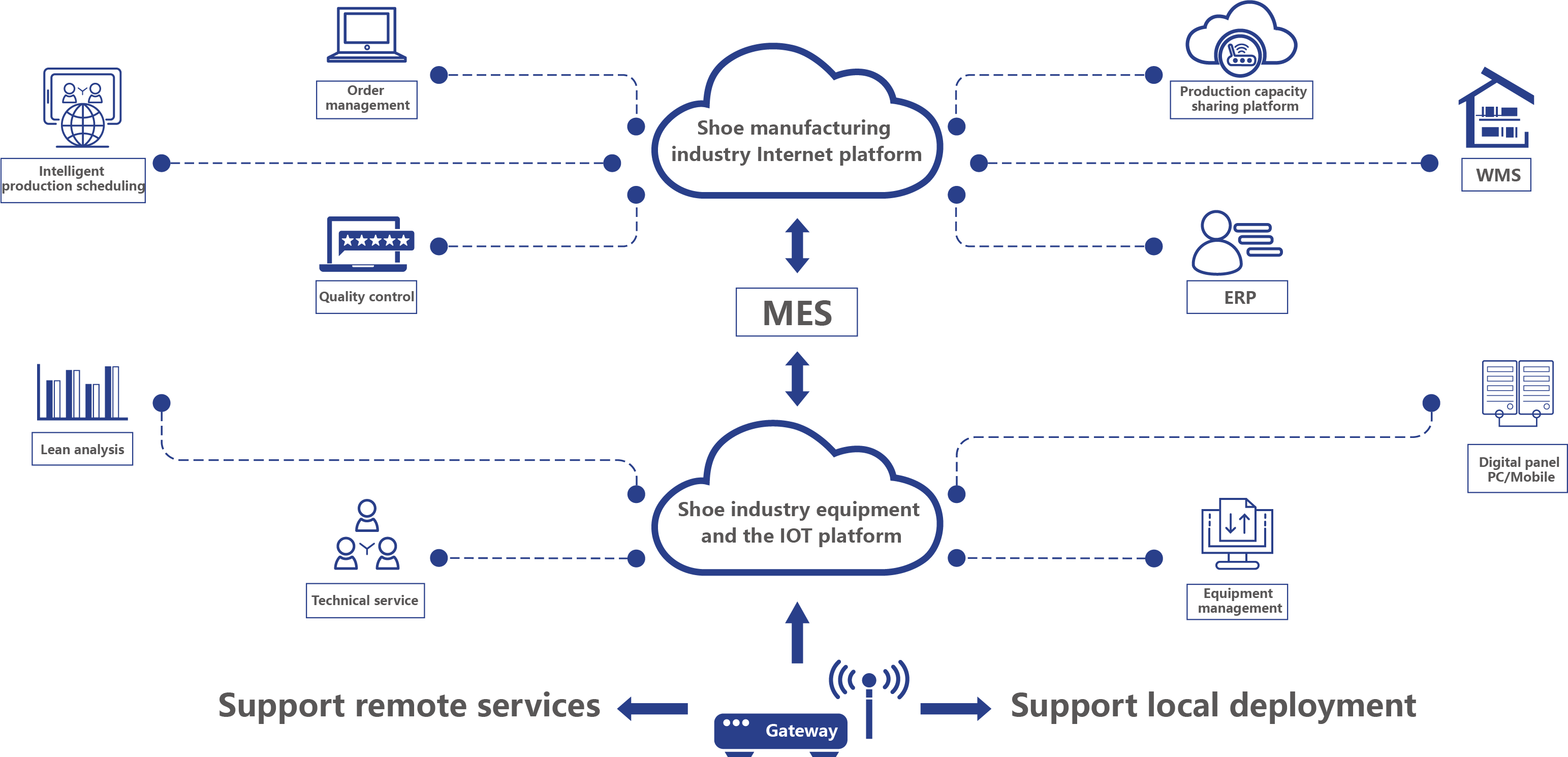

Develop digital platform, build large system, CAD system, MES system, WMS system, SSCM system, APS system import, improve the design efficiency and management level

Intelligentize

Establish a cloud database, connect each system and drive the factory operation, and use the material network, Internet, cloud computing technology

Fully build the C2M business process, to achieve comprehensive and efficient personalized delivery